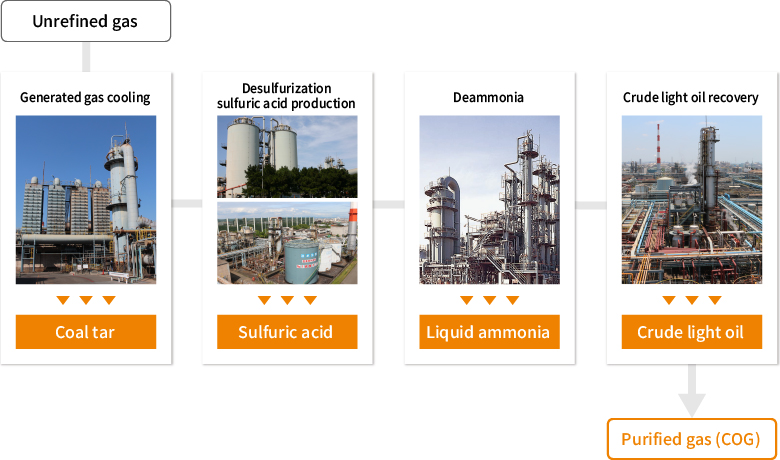

Gas Refining

Coke oven gas, a by-product of the coke manufacturing

process, is used to generate and supply useful chemical

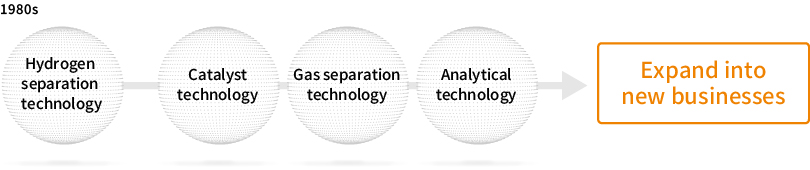

products. The technologies we cultivate through our gas

business are utilized in a variety of fields. We also recover

and reuse the thermal energy that is generated.

Chemical products

- Coal tar

During the first step in the gas purification process, coke oven gas is cooled in a cold collection chamber, and coal tar is extracted as a by-product. Coal tar is used as an anti-rust coating or an anti-corrosive coating, and as a raw material for carbon in tires and golf club shafts.

- Liquid ammonia

In our liquid ammonia facility, the ammonia content in gas is removed by absorption with a phosphoric acid solution, then collected as liquid ammonia through steam distillation. Liquid ammonia is widely used as a denitrification agent in the field of environmental conservation, such as in the removal of NOx emitted from power plants.

- Crude light oil

In our light oil recovery facility, crude light oil in gas is cleaned with an absorbent oil and collected. Crude light oil is used as a raw material for plastics and transformed into a variety of daily necessities.

- Sulfuric acid

In our desulfurization facility, we remove the sulfur content from the gas used in our plant to make it clean. We then use this sulfur content to produce concentrated sulfuric acid in our sulfuric acid manufacturing facility. Sulfuric acid can be used in industrial products, pharmaceuticals, fertilizers, batteries, and many other applications in our daily lives.